Thermal spraying: Precise surface finishing

The DURMAT®product range offers high-quality materials for the following thermal spray processes:

Callback service

Thermal spray processes

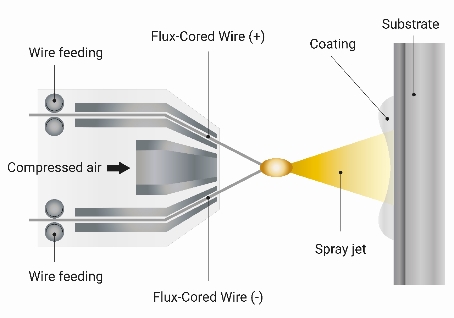

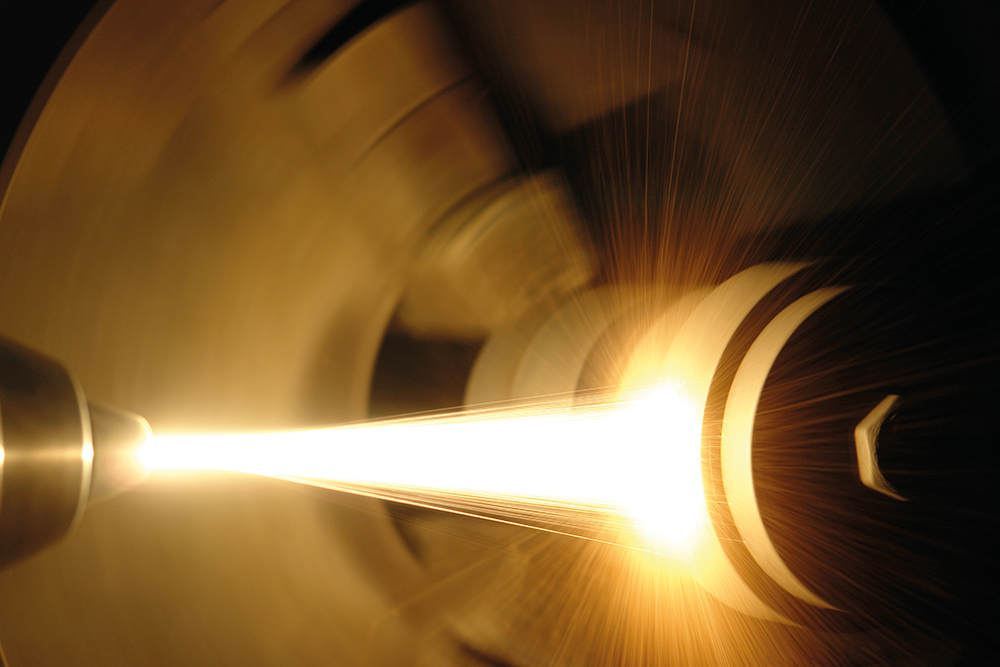

Arc wire spraying (Libo)

Arc spraying is characterized above all by high order rates of up to 80 kg/h and possible production of layer thicknesses of up to several millimeters as well as a very robust technology with easy handling at the same time off. For this reason, the spraying process is often used as a mobile process on construction sites. A decisive advantage of electric arc spraying is the fact that No combustible process gases are required, which makes the process safer and achieves good energy utilization. The main area of application is considered to be the Corrosion and wear protection.

Functionality of arc wire spraying

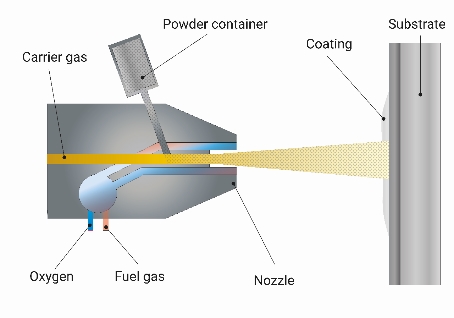

Powder flame spraying

At Powder flame spraying the powdered filler material is melted or fused in the nozzle system of the spray gun with an oxy-acetylene flame (thermal energy) and applied to the intended workpiece areas at the appropriate speed (kinetic energy). If necessary, an additional gas (e.g. argon or nitrogen) can also be used to accelerate the powder particles. The variety of Spray additives is the highest for powders with well over 100 materials very wide range.

In the case of powders, a distinction is made between self-flowing and Self-adhesive powder. The self-flowing powders usually require additional thermal post-treatment. This "melting down" is mainly carried out with the oxy-acetylene burners, which are excellently suited for this purpose.

The thermal process significantly increases the adhesion of sprayed coating to the base material; the sprayed coating is gas and liquid tight.

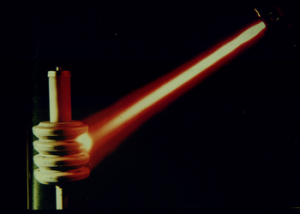

Wire flame spraying

At Wire flame spraying the powdered filler material is melted or fused in the nozzle system of the spray gun with an oxy-acetylene flame (thermal energy) and applied to the intended workpiece areas at the appropriate speed (kinetic energy). If necessary, an additional gas (e.g. argon or nitrogen) can also be used to accelerate the powder particles. The variety of Spray additives is the highest for powders with well over 100 materials very wide range.

In the case of powders, a distinction is made between self-flowing and Self-adhesive powder. The self-flowing powders usually require additional thermal post-treatment. This "melting down" is mainly carried out with the oxy-acetylene burners, which are excellently suited for this purpose.

The thermal process significantly increases the adhesion of sprayed coating to the base material; the sprayed coating is gas and liquid tight.

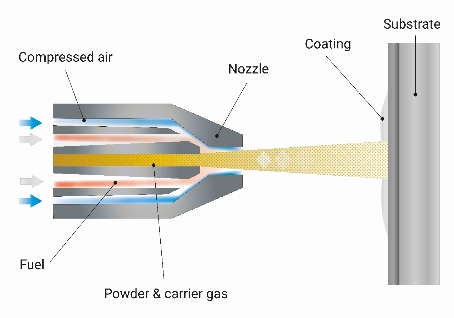

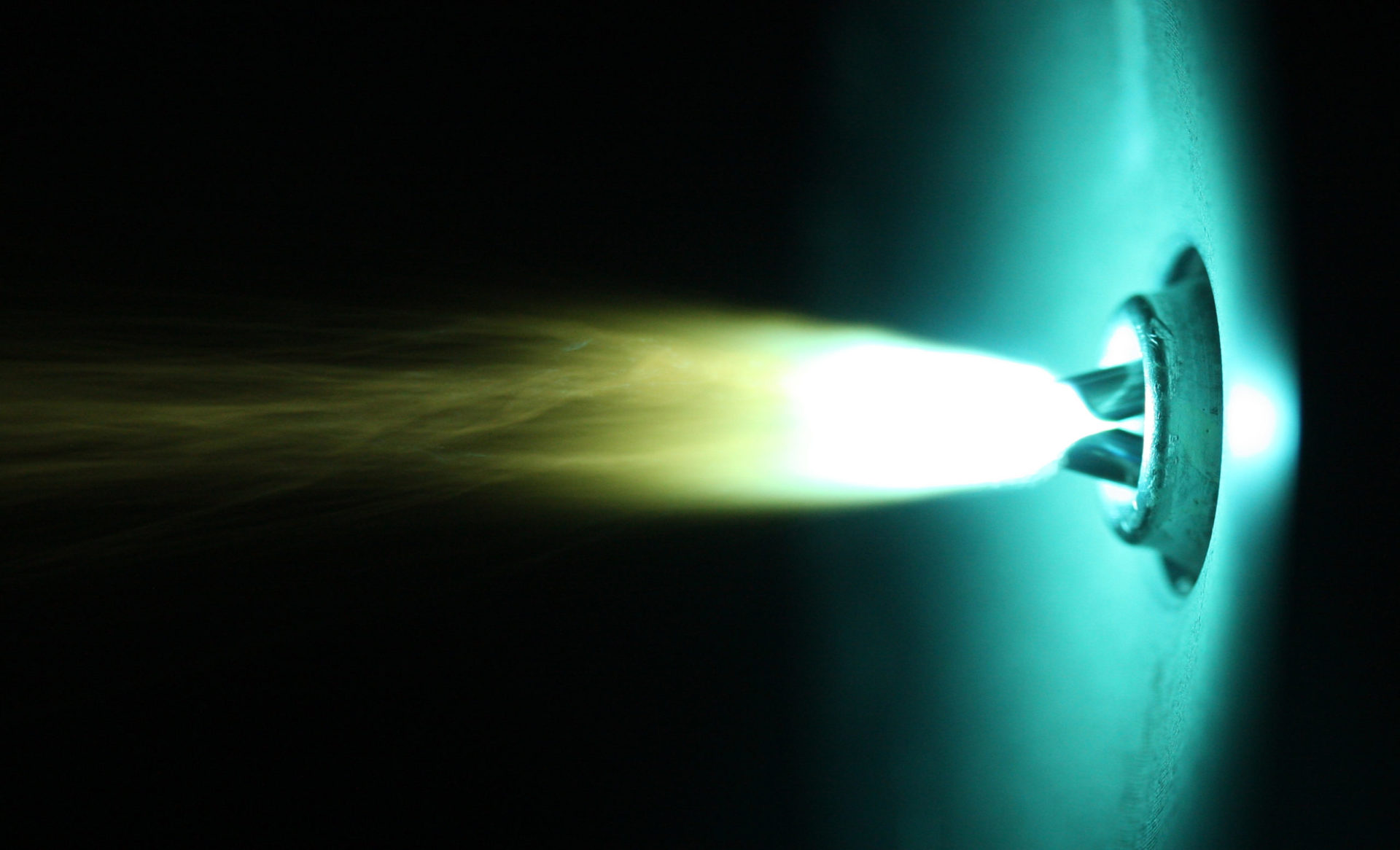

High velocity oxygen fuel spraying (HVOF / HVAF)

High velocity oxygen fuel (HVOF) spraying is a thermal coating process for surface treatment. At High velocity oxygen fuel spraying continuous fuel combustion takes place under high pressure within a water- or air-cooled combustion chamber. Fuels used are fuel gases (such as propane, ethylene, propene, butane, acetylene, hydrogen), liquid fuels (e.g. diesel, kerosene), and also combinations of these. The oxidant is mostly Oxygenbut also air (common process designation: HVAF, derived from High-Velocity-Air-Fuel). The high pressure of the burning fuel-oxygen mixture generated in the combustion chamber and the (usually downstream) expansion nozzle (Laval nozzle) create the necessary High speed of the gas jet.

Mostly powdered spray materials (particle size 1-150 µm), but also available as rods and wires, are axial in the combustion chamber or radial is supplied in the area of the expansion nozzle. This accelerates the spray particles to the high velocities that result in very dense spray layers with excellent adhesion properties lead. Due to the controllable and just sufficient heat input, the spray material is only slightly metallurgically changed by the spraying process.

Areas of application are: Power plants, aviation, automotive, paper and mechanical engineering industries.

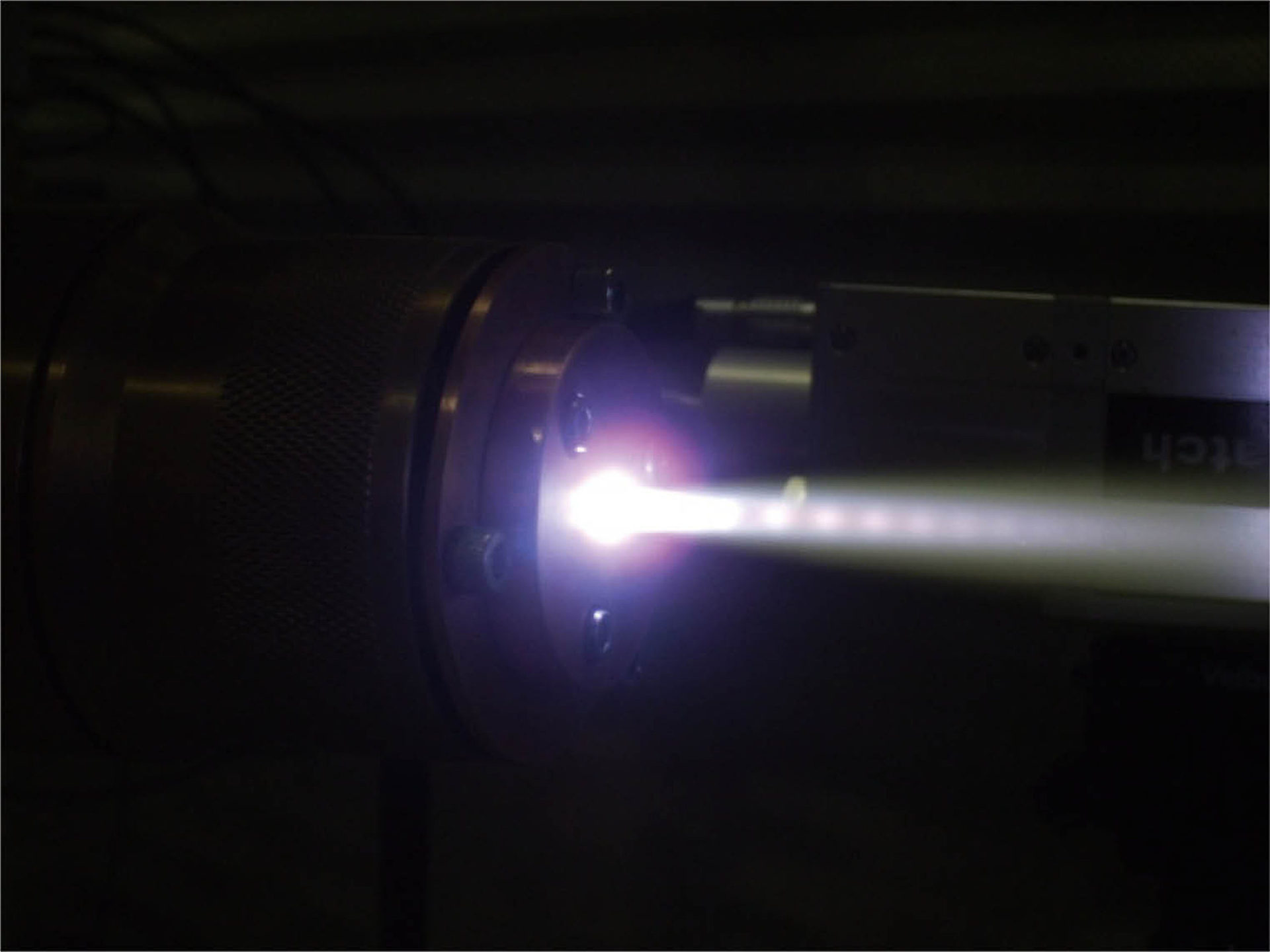

Plasma syringes

At Atmospheric Plasma Spraying (APS) an anode and up to three cathodes are separated by a narrow gap in a plasma torch. An arc is generated between the anode and cathode by a DC voltage. The gas or gas mixture flowing through the plasma torch is passed through the arc and ionized in the process. The dissociation, or subsequent ionization, produces a highly heated (up to 20000 K), electrically conductive gas of positive ions and electrons.

In this generated Plasmajet powder (usual particle size distribution: 5-120 µm, with certain instruments a particle size down to 100 nm is also possible) is injected, which is High plasma temperature is melted. The plasma flow entrains the powder particles and hurls them onto the workpiece/component/substrate to be coated. The gas molecules return to a stable state after a very short time, and so the plasma temperature drops again after only a short distance.

Application of the plasma coating and further procedure

The Plasma coating takes place in normal atmosphere, inert atmosphere (under inert gas such as argon), in vacuum or also under water. For the coating quality, the speed, temperature and composition of the coating of the plasma gas is of importance. Special modifications such as the PTWA (PTWA process for Plasma Transferred Wire Arc) use a wire instead of powder, resulting in a simpler torch design. Plasma spraying under vacuum is referred to as VPS designated.

At Inert gas plasma spraying the entire process is carried out with inert gas (usually nitrogen) as the transport gas. The advantage here is the very low oxidation of the particles between the burner and the substrate.

Gases used are argon, nitrogen, hydrogen, helium or combinations thereof. Due to the very different process parameters, a Variety of coatings so that there are fields of application in almost every industry. Important industries in which Plasma syringes used are the automotive industry, the paper and printing industry, the aerospace industry, the waste industry and the power generating industry.