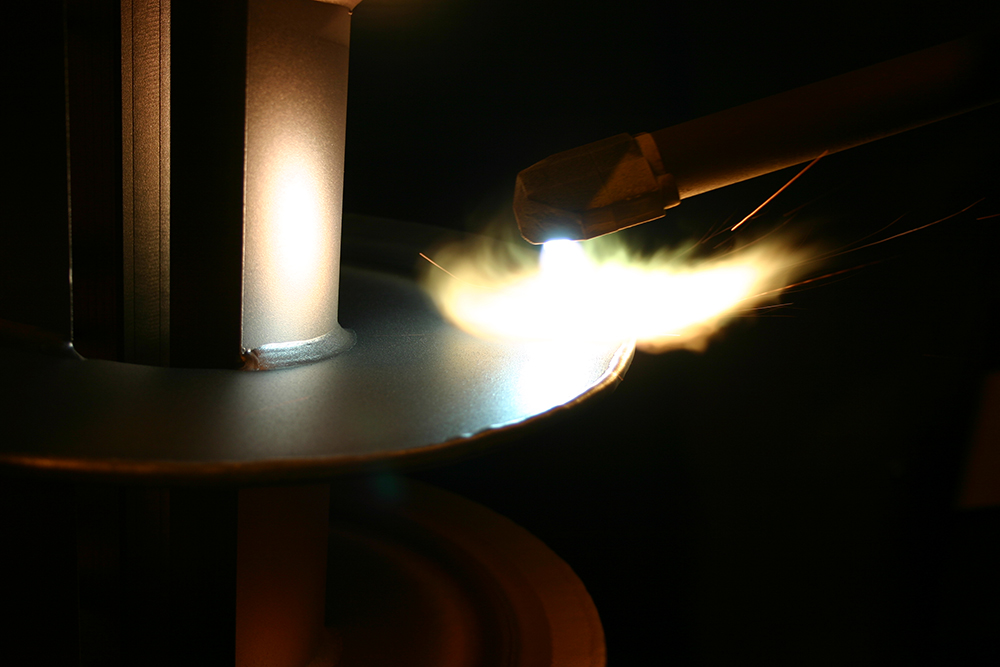

Powder, rods and wires for oxyacetylene welding

| DURMAT® | C | Si | Mn | Cr | Ni | B | Hardness | Composition | Applications | Features | Classification |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 40-A | 0,2-0,35 | 3,8 | – | 07 Sep | Rest | 1,4-1,7 | 36-40 HRC | – | Small surfaces or edges on dies; in mold making, in the glass industry; fittings, pump pistons and guides. Suitable for cold forming tools as well as Cr and CrNi steels. | Good sliding behavior against steels with high strength and plastics Rust and acid resistant Cavitation and erosion resistant Highly wear- and heat-resistant up to approx. 550 °C | DIN EN 14700 | DIN 8555 | -106/+22 |

| 60-A | 0,6-0,8 | 3,8 | – | 15-17 | Rest | 2,8-3,4 | 57-60 HRC | – | Small surfaces or edges on dies; in mold making in the glass industry; fittings, pump pistons and guides. Suitable for cold forming tools as well as Cr and CrNi steels. | Good sliding behavior against steels with high strength and plastics Rust and acid resistant Cavitation and erosion resistant Highly wear- and heat-resistant up to approx. 550 °C | DIN EN 14700 | DIN 8555 | -106/+22 |

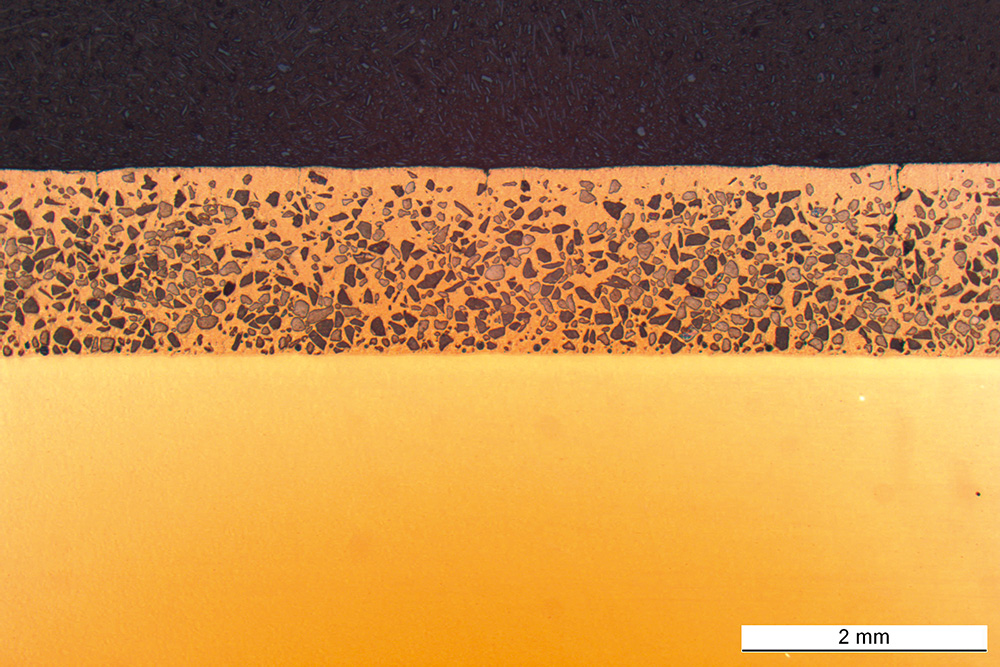

| 40-WSC | 0,6-0,8 | 3,8 | – | 15-17 | Rest | 2,8-3,4 | Matrix: 57-60 HRC | 60% 60-A + 40% WSC | Protection against mechanical and mineral wear of highly stressed components (e.g. machine and apparatus construction, pump and mill construction, stoneware industry, deep drilling tools, excavator parts and other wear parts) | Good sliding behavior against steels with high strength and plastics Rust and acid resistant Cavitation and erosion resistant Highly wear- and heat-resistant up to approx. 550 °C | DIN EN 14700 | DIN 8555 | -106/+22 |

| 50-WSC | 0,6-0,8 | 3,8 | – | 15-17 | Rest | 2,8-3,4 | Matrix: 57-60 HRC | 50% 60-A + 50% WSC | Protection against mechanical and mineral wear of highly stressed components (e.g. machine and apparatus construction, pump and mill construction, stoneware industry, deep drilling tools, excavator parts and other wear parts) | Good sliding behavior against steels with high strength and plastics Rust and acid resistant Cavitation and erosion resistant Highly wear- and heat-resistant up to approx. 550 °C | DIN EN 14700 | DIN 8555 | -106/+22 |

| 60-WSC | 0,6-0,8 | 3,8 | – | 15-17 | Rest | 2,8-3,4 | Matrix: 57-60 HRC | 40% 60-A + 60% WSC | Protection against mechanical and mineral wear of highly stressed components (e.g. machine and apparatus construction, pump and mill construction, stoneware industry, deep drilling tools, excavator parts and other wear parts) | Good sliding behavior against steels with high strength and plastics Rust and acid resistant Cavitation and erosion resistant Highly wear- and heat-resistant up to approx. 550 °C | DIN EN 14700 | DIN 8555 | -106/+22 |

| 75-WSC | 0,6-0,8 | 3,8 | – | 15-17 | Rest | 2,8-3,4 | Matrix: 57-60 HRC | 25% 60-A + 75% WSC | Protection against mechanical and mineral wear of highly stressed components (e.g. machine and apparatus construction, pump and mill construction, stoneware industry, deep drilling tools, excavator parts and other wear parts) | Good sliding behavior against steels with high strength and plastics Rust and acid resistant Cavitation and erosion resistant Highly wear- and heat-resistant up to approx. 550 °C | DIN EN 14700 | DIN 8555 | -106/+22 |

| 80-WSC | 0,6-0,8 | 3,8 | – | 15-17 | Rest | 2,8-3,4 | Matrix: 57-60 HRC | 20% 60-A + 80% WSC | Protection against mechanical and mineral wear of highly stressed components (e.g. machine and apparatus construction, pump and mill construction, stoneware industry, deep drilling tools, excavator parts and other wear parts) | Good sliding behavior against steels with high strength and plastics Rust and acid resistant Cavitation and erosion resistant Highly wear- and heat-resistant up to approx. 550 °C | DIN EN 14700 | DIN 8555 | -106/+22 |

- Request information material

Notice: The mandatory field is marked. All other fields are voluntary. Your data will only be collected and stored electronically strictly for the purpose of processing and responding to your request. Information on data processing can be found here: Privacy.

More products

Nickel base (Ni)

Nickel base (Ni)

The main field of application is armoring of hammer saddles, hot shear blades, stretching inserts.

About the product