Quality assurance for best wear protection solutions

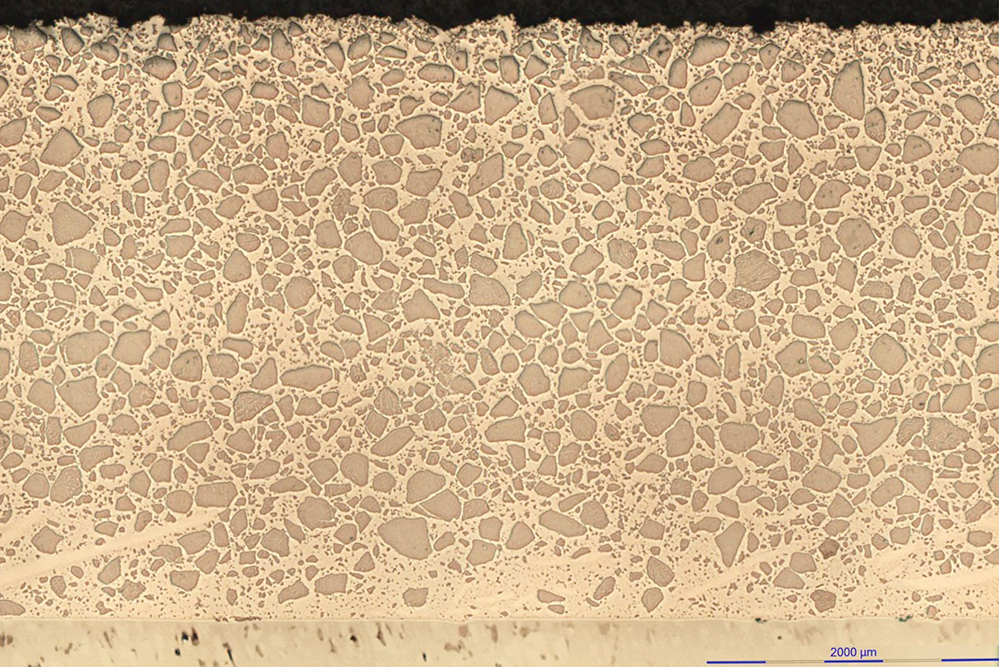

At the Quality of our products and solutions, we do not concern ourselves with externals - because the inner values such as the structure and chemical composition of the Materials is crucial for excellent results.

In In-house laboratories we therefore determine the Material characteristics of all substances involved in the process and document them seamlessly - from the incoming inspection of raw materials to the alloying constituents of a finished buildup weld. With its own Metallography Lab, a Spray Lab and a Wear laboratory the company has three in-house facilities for quality control and further development of all products.

Precise analytics is our element

With state-of-the-art spectrometric Analysis method and more demanding Materials Testing Technology we monitor, test and document every single raw material batch in the process chain. In addition, we develop for customers customized products for special wear solutions or adapt existing solutions. As a certified company according to ISO 9001:2015 DURUM guarantees the high quality of every single delivery and assures you the best Quality of results when using DURUM wear protection solutions.

We export our services and products to over 80 countries worldwide.

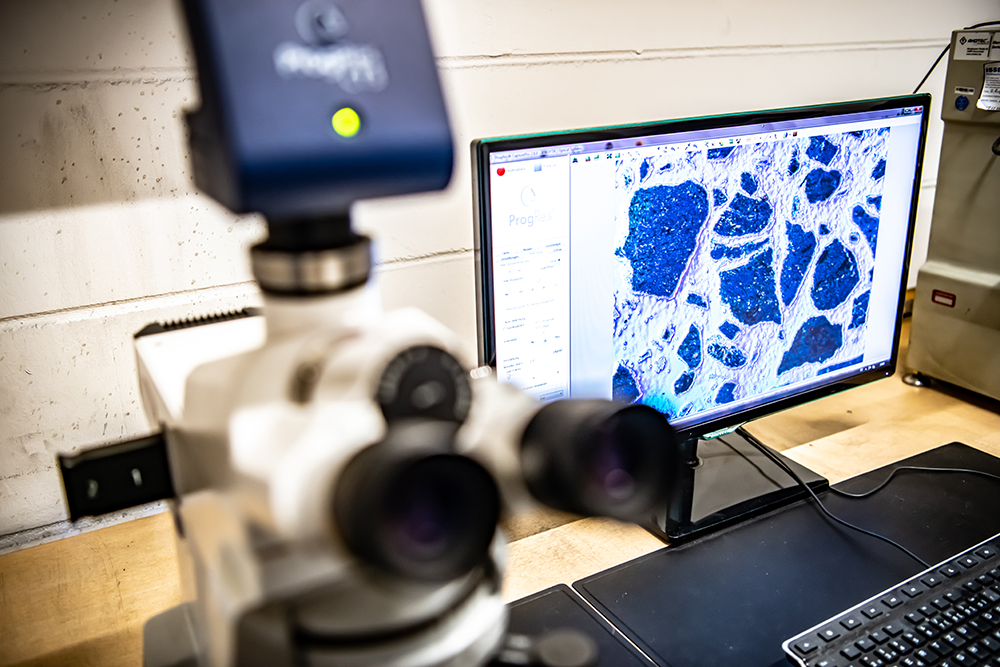

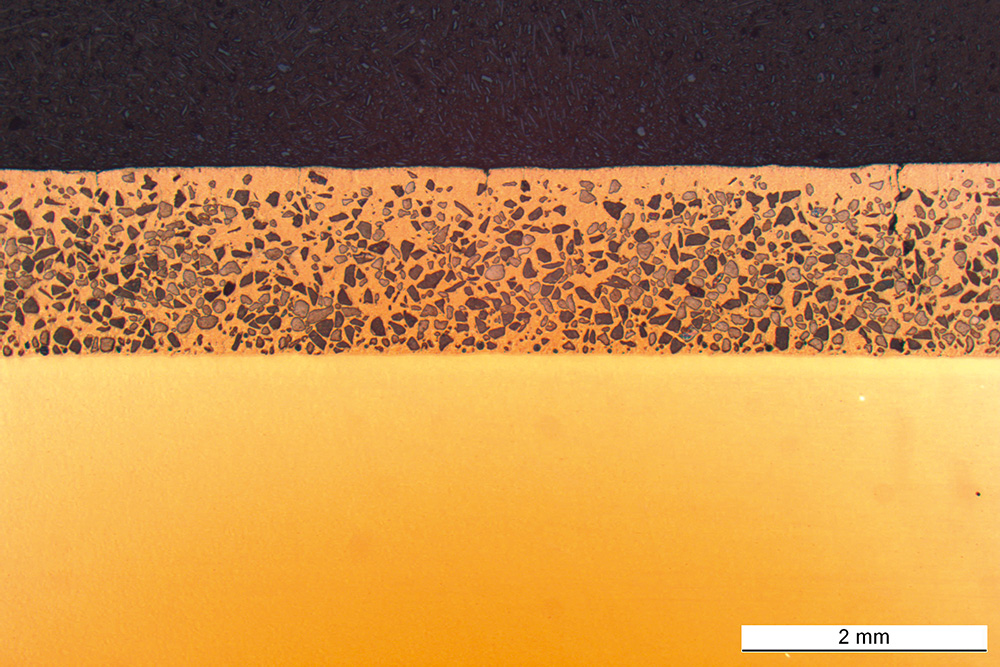

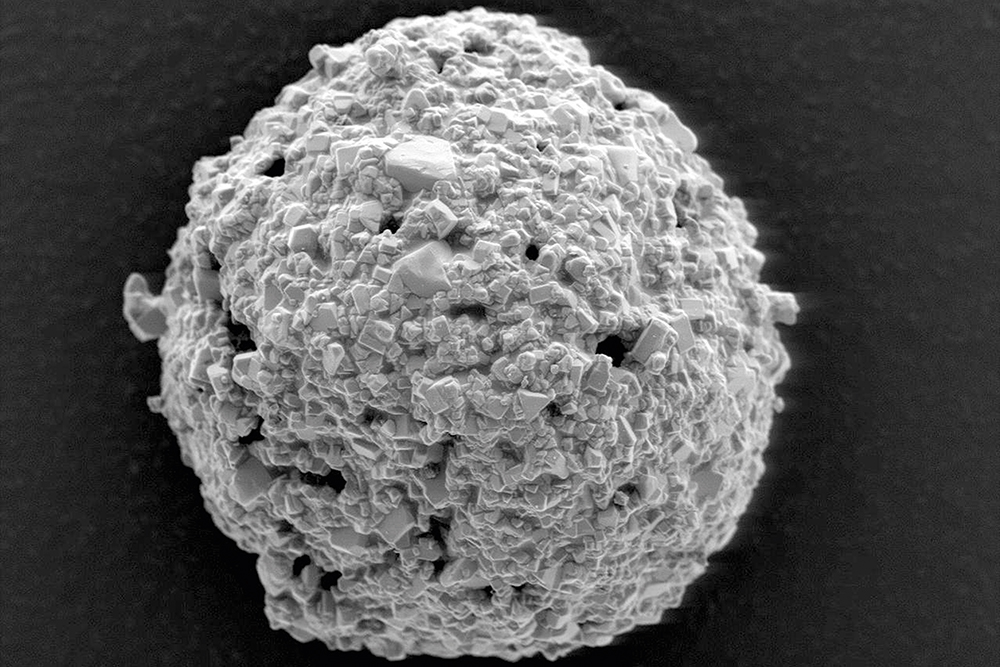

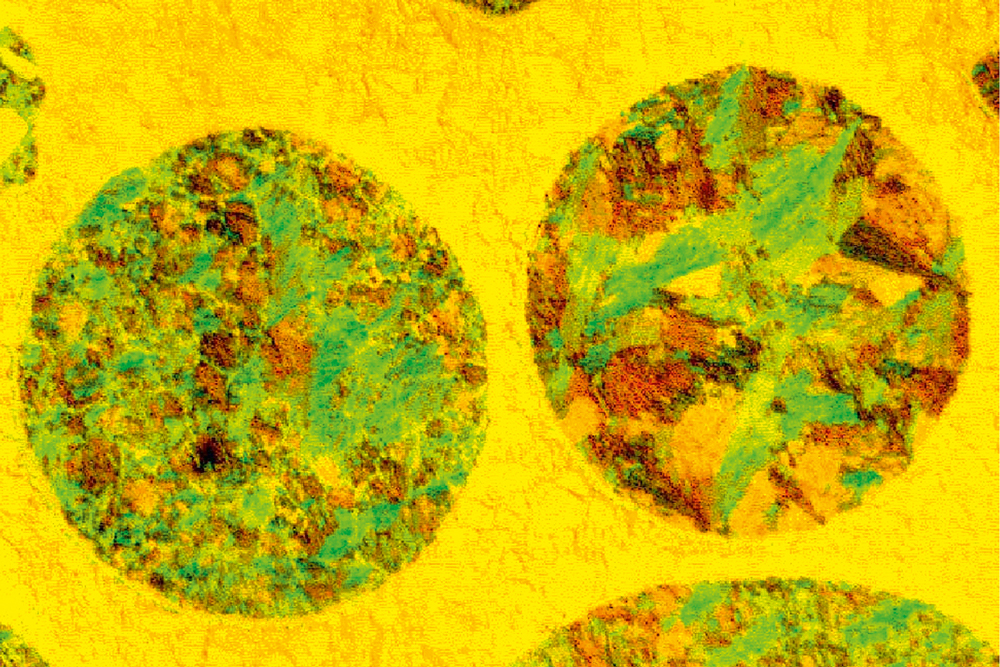

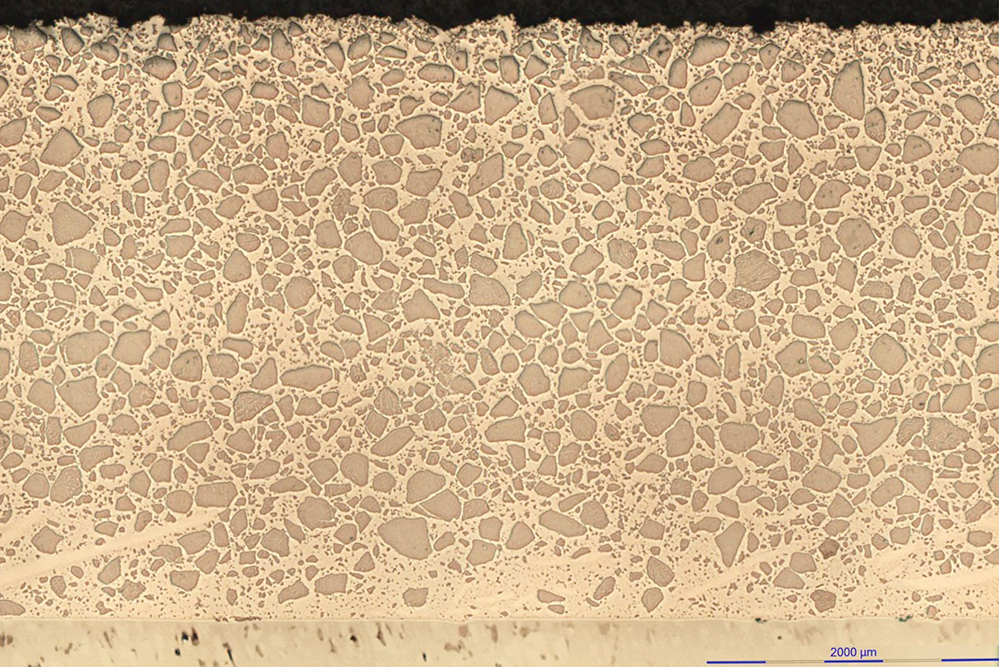

Metallography Lab

Equipment

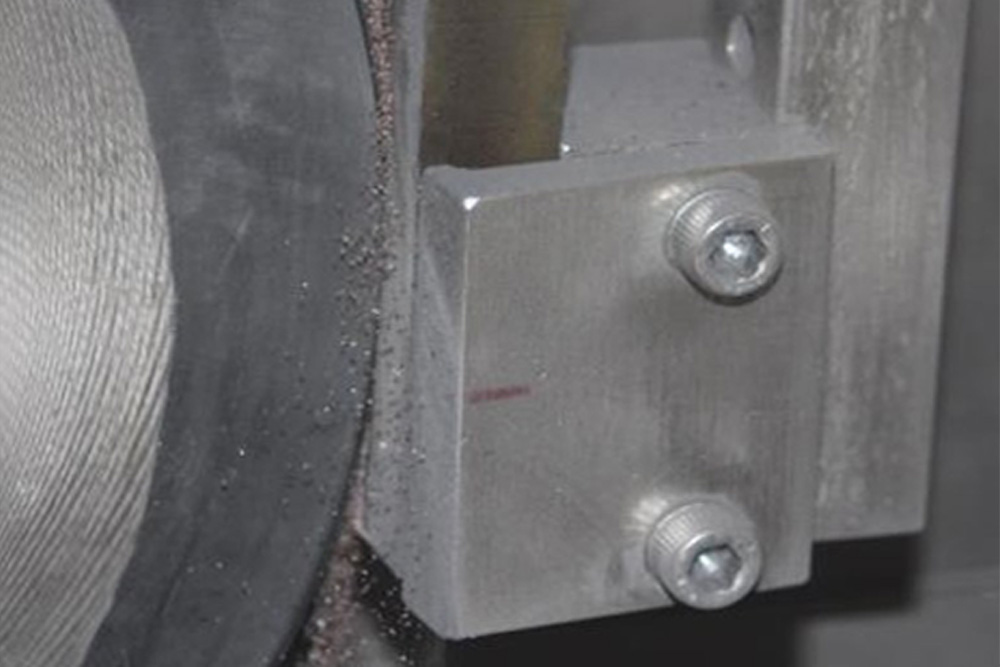

- Automatic wet cutting machine

- Cold and hot embedding machine

- Grinding and polishing semi-automatic machine

- Digital microscope with differential interference contrast (DIC)

- Reflected light microscope

- Rockwell and Vickers hardness tester for micro and macro hardness measurement

- Bruker Q4 Tasman Radio Spectrometer

- ROTAP sieve analysis

- MicroTrac Laser Diffraction Particle Sizer

- Hall-flow and bulk density meter

Thermal spray laboratory

DURUM has its own Spray Lab for thermal spraying. Here the qualitative monitoring the DURMAT® Spray wires and spray powders for arc wire spraying with the SPS-controlled spraying system for flux cored wires - DURSPRAY 450 - as well as powder flame spraying. Furthermore we manufacture in the spraying laboratory Pattern and Small components.

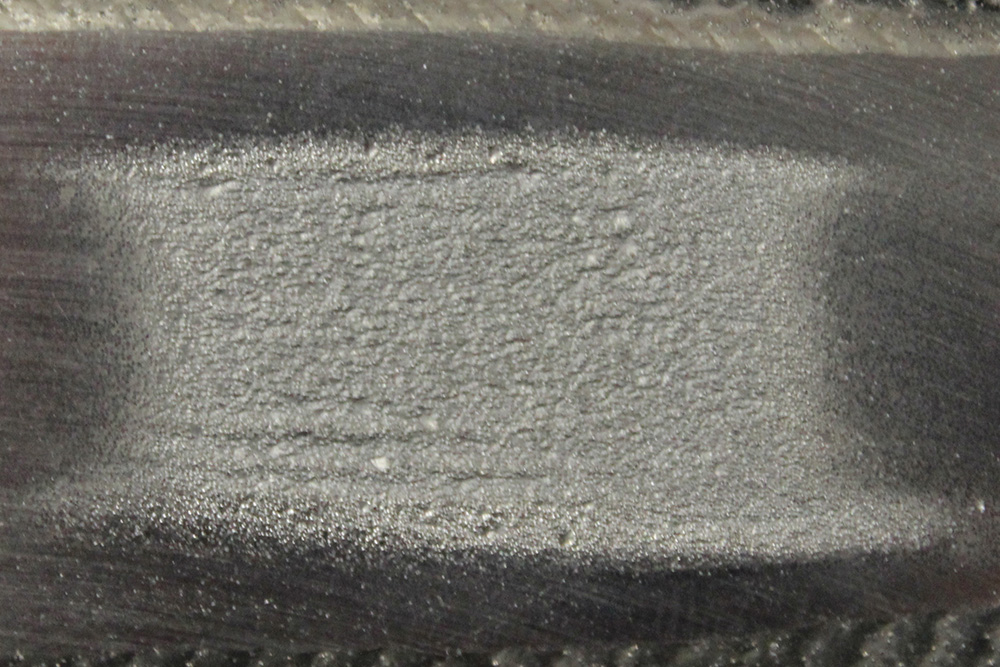

Welding laboratory

In the DURUM welding laboratory, in addition to the technical welding Quality monitoring the DURMAT®-welding products (PTA, MIG/MAG/OA, submerged arc, cobalt-based alloys, oxy, arc hand, TIG) mainly Test welds of newly developed alloys as well as Sample welds at the request of the customer. Likewise, here we test all PTA systems DURWELD thoroughly before they are shipped for sale. Due to our long experience and practice with DURMAT®-welding products, we can offer our customers the best products for specific applications to offer.

Wear laboratory

DURUM has its own Wear laboratoryin which we test products already established on the market as well as newly developed alloys in terms of wear resistance. The wear laboratory includes the in ASTM G65 standardized friction wheel test as well as the ASTM G75 standardized Miller test.

In collaboration with our customers, we develop and test wear-resistant alloys in order to jointly optimal wear protection solutions for the corresponding use cases.