Oxyacetylene welding

Overview table

| DURMAT® | Chem. composition | Hardness | Applications | Features | Classification |

|---|---|---|---|---|---|

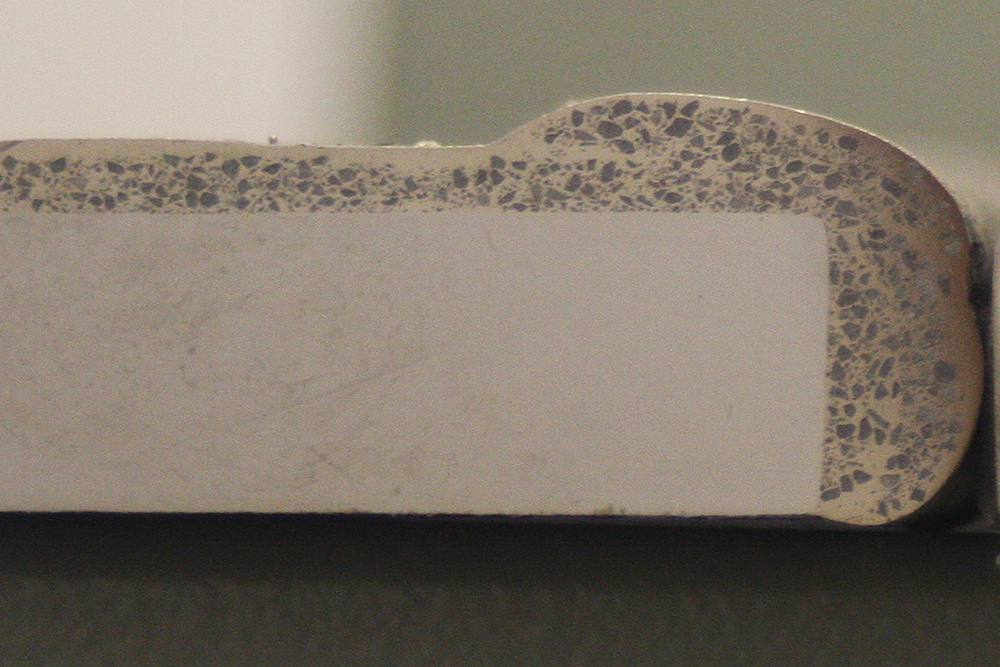

| A | Fe base with WSC | WSC: 2.360 HV0.1 Mixed hardness of weld metal: 55 HRC | Tools and machine parts | Oxyacetylene rod for hardfacing on non-alloy and low-alloy steels | T Fe20 | G21-GF-55-CG |

| A-PLUS | Fe base with SWSC | SWSC: 3.000 HV0.1 Mixed hardness of weld metal: 55 HRC | Tools and machine parts | Similar to DURMAT® A, but filled with spherical tungsten fused carbide (SWSC). | T Fe20 | G21-GF-55-CG |

| B | NiCrBSi base with WSC | WSC: 2.360 HV0.1 NiCrBSi alloy: 420-450 HV0.1 | Deposition welding against abrasion and conditional corrosion, e.g. on cast iron, ferritic and austenitic steels, mixer blades, preparation plants for molding sand, pump valves, screw conveyors, grinding plates and on parts in the deep drilling industry | Flexible, bendable welding rod | T Ni20 | G21-UM-55-CG |

| BK | NiCrBSi base with SWSC | SWSC: 3.000 HV0.1 | Deposition welding against abrasion and conditional corrosion, e.g. on cast iron, ferritic and austenitic steels, mixer blades, preparation plants for molding sand, pump valves, screw conveyors, grinding plates and on parts in the deep drilling industry | Similar to DURMAT® B, but filled with spherical tungsten fused carbide (SWSC). | T Ni20 | G21-UM-55-CG |

| NIA | NiCrBSi base with WSC | WSC: 2.360 HV0.1 | Mixer blades, processing plants for molding sand, slurry pump valves, screw conveyors, deep drilling tools, corrosion-resistant coatings against heavy abrasive wear in the chemical and food industries | Oxyacetylene rod with very high resistance to abrasion High resistance of the matrix to acids, alkalis and other corrosive media | T Ni20 | G21-GF-55-CG |

| NIA-PLUS | NiCrBSi base with SWSC | SWSC: 3.000 HV0.1 | Mixer blades, processing plants for molding sand, slurry pump valves, screw conveyors, deep drilling tools, corrosion-resistant coatings against heavy abrasive wear in the chemical and food industries | Similar to DURMAT® NIA, but filled with spherical tungsten fused carbide (SWSC). | T Ni20 | G21-GF-55-CG |

| CS | Cu-Ni-Zn matrix with solid carbide grains | - | Special use in deep drilling technology, e.g. for hardfacing overdrill bits, face milling cutters, six-wing mei.els, etc. | Uniform embedding of the carbide grains in the matrix | - |

| TINNING-RODS | Nickel bronze bars | - | Coatings on drilling rigs for oil and gas production in combination with DURMAT® CS | Nickel-bronze rods with a 10 % nickel content for autogenous brazing on | - |

- Request information material

Notice: The mandatory field is marked. All other fields are voluntary. Your data will only be collected and stored electronically strictly for the purpose of processing and responding to your request. Information on data processing can be found here: Privacy.

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationMore products

DURUM - Made in GERMANY

We manufacture our wear protection solutions for you exclusively in Germany.