Flux-cored welding

Overview table

| DURMAT® | Chem. composition: | Hardness: | Applications: | Features: | Classification: |

|---|---|---|---|---|---|

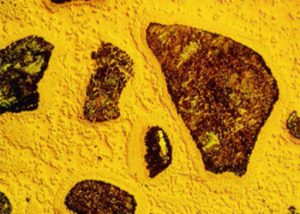

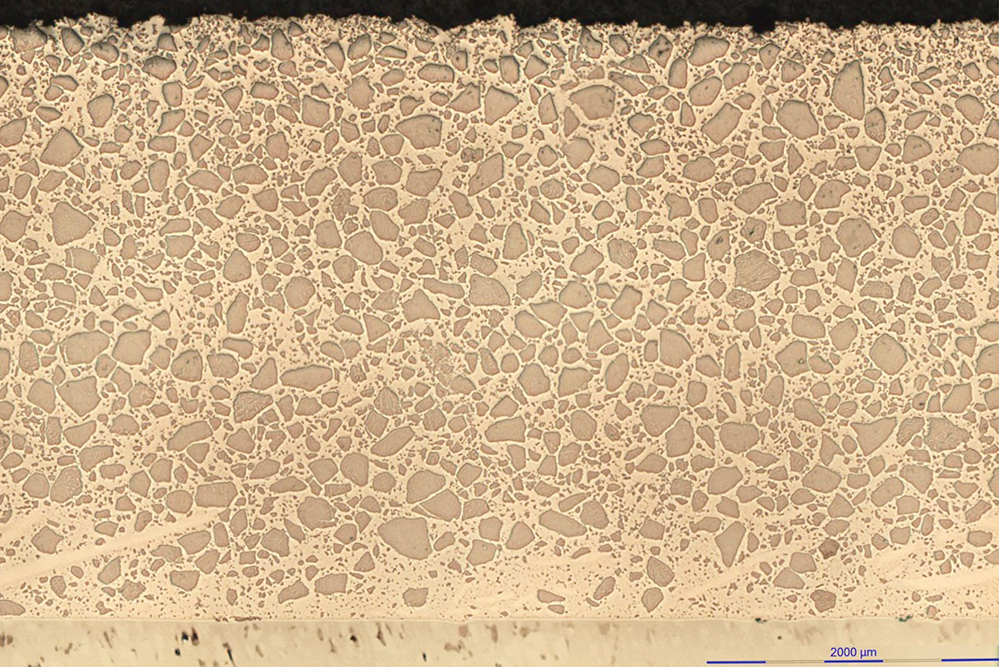

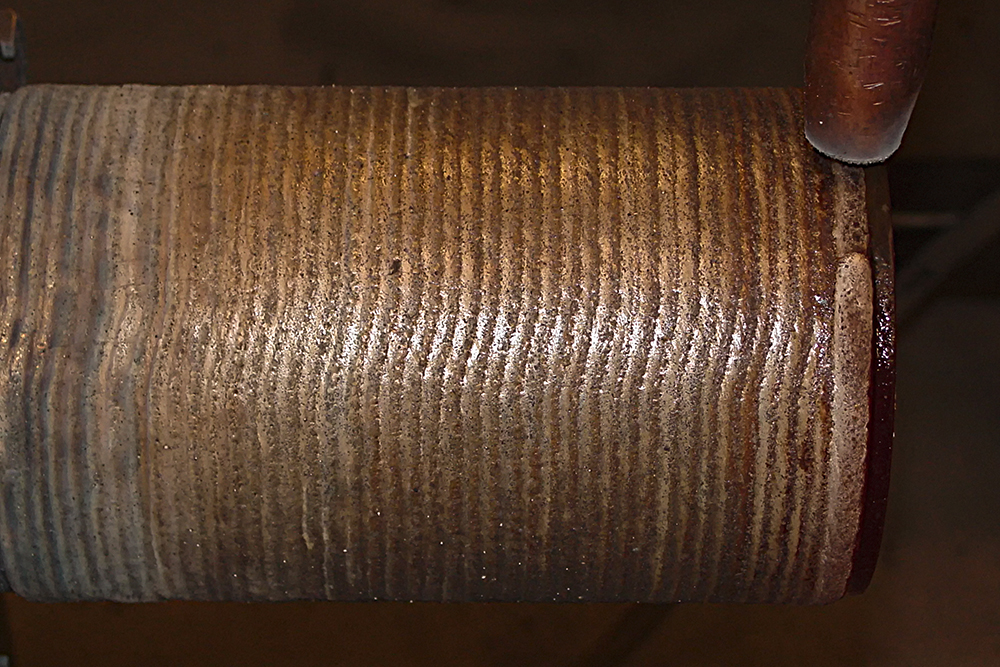

| OA | Fe matrix with 50-62% WSC | WSC: 2.360HV0.1 Weld metal: 64-66 HRC1.layer 66-68 HRC2.Position | Mining, stone industry, deep drilling technology, etc. | Flux cored wire electrode for semi-automatic buildup welding Weld metal resists extremely abrasive wear | T Fe20| MF 21-65GZ |

| NICRW | NiCr matrix with 50-62% WSC | WSC: 2.360HV0.1 Matrix: 490-540HV0.1 | Tools in the deep drilling industry as well as ferritic and austenitic parts of the chemical and food industry | Cored wire for extremely wear-resistant coatings Very good heat and corrosion resistance Weld metal can only be ground to a limited extent | T Fe20| MF 21-65GZ |

| NIFD | Ni-Matrix with 50-62% WSC | WSC: 2.360HV0.1 | Tools in the deep drilling industry as well as ferritic and austenitic parts of the chemical and food industry | Cored wire for extremely wear-resistant coatings Very good heat and corrosion resistance Weld metal can only be ground to a limited extent | T Ni20| MF 21-55-CGTZ |

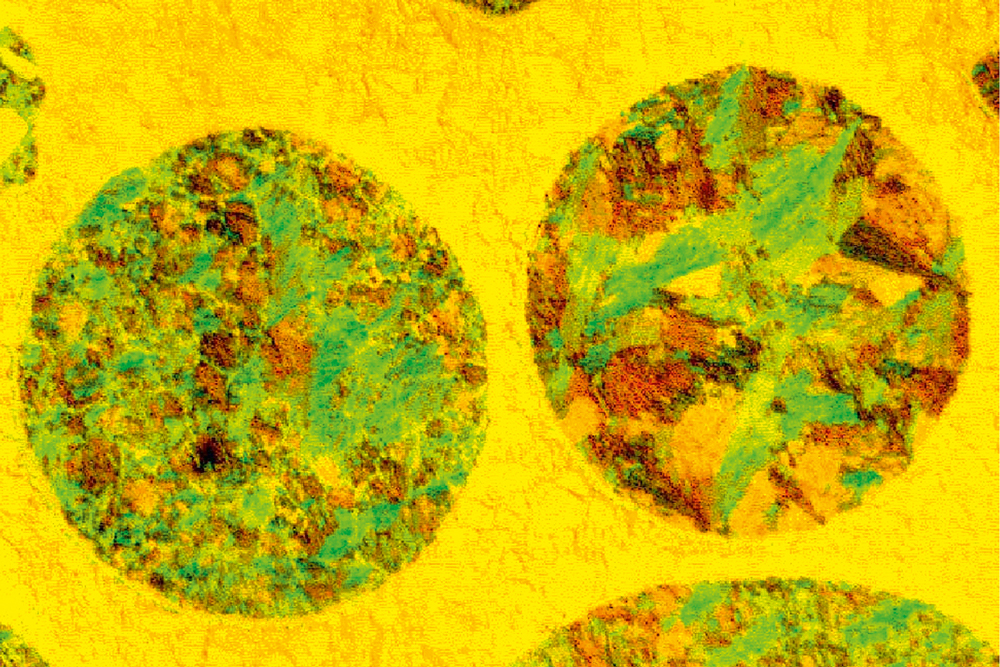

| NIFD - PLUS | Ni-Matrix with 50-63% SWSC | SWSC: 3.000HV0.1 | Tools in the deep drilling industry as well as ferritic and austenitic parts of the chemical and food industry | Similar to DURMAT® NIFD, but filled with spherical tungsten fused carbide (SWSC) | T Ni20| MF21-55-CGZ |

| NI2 | Ni-Matrix with 50-62% WSC and special carbides (SC) | WSC: 2.360HV0.1 Matrix: 450-480HV0.1 Special carbides (SC): 2,900HV0.1 | Tools in the deep drilling industry, mining, ceramics industry, as well as ferritic and austenitic parts in the chemical and food industry. | Very good heat and corrosion resistance Further improved abrasion resistance compared to DURMAT® NIFD | T Ni20| MF21-55-CGZ |

| NI2 - PLUS | Ni-Matrix with 50-62% SWSC and special carbides (SC) | SWSC: 3.000HV0.1 Matrix: 450-480HV0.1 Special carbides (SC): 2,900HV0.1 | Tools in the deep drilling industry, mining, ceramics industry, as well as ferritic and austenitic parts in the chemical and food industry. | Similar to DURMAT® NI2, but filled with spherical tungsten fused carbide (SWSC) | T Ni20| MF21-55-CGZ |

| FD 773 | NiCr matrix with 50-62% RF 13 | RF 13: >1,950-2,050HV0.1 Matrix: 490-540HV0.1 | Protection of surfaces against extremely abrasive wear and corrosion | Good corrosion protection in chloride-containing media | T Ni20| MF 21-55-CGZ |

| FD 774 | Co-matrix with 50-62% RF 13 | RF 13: >1,950-2,050HV0.1 Matrix: 450-480HV0.1 | Protection of surfaces against extremely abrasive wear and corrosion | Good corrosion protection in chloride-containing media | T Ni20| MF 21-55-CGZ |

| FD 778 | NiFe matrix with 50-62% WSC | WSC: 2.360HV0.1 Matrix: 490-540HV0.1 | Protection of surfaces against extremely abrasive wear and corrosion | Low melting point Smooth and clean surface Good resistance to corrosive media | T Ni20| MF 21-55-CGZ |

| FD 779 | Ni-Matrix with 50-62% MCWC | MCWC: >1,600HV0.1 Matrix: 490-540HV0.1 | Protection of surfaces against extremely abrasive wear and corrosion | Low melting point Smooth and clean surface | T Ni20| MF 21-55-CGZ |

| FD 780 | NiFe matrix with 50-62% MCWC | MCWC: >1,600HV0.1 Matrix: 490-540HV0.1 | Protection of surfaces against extremely abrasive wear and corrosion | Low melting point Smooth and clean surface Good resistance to corrosive media | T Ni20| MF 21-55-CGZ |

| FD 789 | Ni-Matrix with 50-62% RF 13 | RF 13: >1,950-2,050HV0.1 Matrix: 450-480HV0.1 | Protection of surfaces against extremely abrasive wear and corrosion | Good corrosion protection against chloride-containing media | T Ni20| MF 21-55-CGZ |

- Request information material

Notice: The mandatory field is marked. All other fields are voluntary. Your data will only be collected and stored electronically strictly for the purpose of processing and responding to your request. Information on data processing can be found here: Privacy.

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationMore products

DURUM - Made in GERMANY

We manufacture our wear protection solutions for you exclusively in Germany.