Cobalt-based alloys

Typical chemical composition* (in wt.-%) of pure weld metal

| DUROLOY® | C | Si | Mn | Cr | Ni | Mo | W | Co | Fe | + | Hardness | Applications | Features | Classification |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DUROLIT 1 | 2,4 | 0,7 | 0,4 | 28 | - | - | 11,5 | Rest | <4 | - | 55 HRC 600 °C: 44 HRC 800 °C: 34 HRC | Repair of forging dies. | Austenitic weld metal with large number of embedded carbides. Very hard, heat resistant, extremely abrasion resistant, corrosion resistant, especially against reducing acids and scale resistant up to approx. 1,000 °C. | DIN EN 14700: T Co3 / DIN 8555: MF 20-55-CGTZ |

| DUROLIT 6 | 1,1 | 1,2 | 0,7 | 29 | - | - | 4,5 | Rest | <4 | - | 40-43 HRC 300 °C: 35 HRC 600 °C: 29 HRC | Steam valves, hot shear blades, high temperature liquid pumps, internal combustion engine valves such as marine diesel, etc. | Tough cobalt-based alloy of austenitic-ledeburitic structure with intercalated Cr and W carbides, machinable. Resists high abrasion and corrosive attack. Impact and thermal shock resistant. | DIN EN 14700: T Co2 / DIN 8555: MF 20-45-CTZ |

| DUROLIT 6 LC | 0,9 | 1,2 | 0,7 | 29 | - | - | 4,5 | Rest | <4 | - | 36-39 HRC | Steam valves, hot shear blades, high temperature liquid pumps, etc. | Austenitic weld metal with intercalated Cr and W carbides. Resists high abrasion, corrosive attack, hard knocks. Resistant to thermal shock. High toughness. | DIN EN 14700: T Co2 / DIN 8555: MF 20-40-CTZ |

| DUROLIT 6 HC | 1,3 | 1,2 | 0,7 | 29 | - | - | 4,5 | Rest | <4 | - | 43-46 HRC | Hot shear blades, steam valves, high temperature liquid pumps, etc. | Austenitic weld metal with intercalated Cr and W carbides. Resists high abrasion and corrosive attack. Impact and thermal shock resistant. | DIN EN 14700: T Co2 / DIN 8555: MF 20-45-CTZ |

| DUROLIT 12 | 1,4 | 1 | 0,8 | 29 | - | - | 8 | Rest | <4 | - | 45-48 HRC 300 °C: 37 HRC 600 °C: 32 HRC | Machining tools of the hardwood, paper and plastics industries, as well as for crushing hammers, valve spindles and earth drills. | Weld metal of austenitic-ledeburitic structure with intercalated Cr and W carbides. Resists high abrasion and corrosive attack. Thermal shock resistant. | DIN EN 14700: T Co3 / DIN 8555: MF 20-50 CTZ |

| DUROLIT 21 | 0,25 | 1 | 0,8 | 28 | 2,5 | 5,5 | - | Rest | <4 | - | 30 HRC Work hardened: 45 HRC | Steam fittings, acid fittings in chemical industry, outlet valves, hot stamping dies. | Tough cobalt-based alloy of austenitic structure. Toughest, most corrosion resistant and high-temperature resistant of the common cobalt hard alloys. Work hardening. | DIN EN 14700: T Co1 / DIN 8555: MF 20-350-CKTZ |

| DUROLIT 21 LC | 0,2 | 1 | 0,8 | 28 | 2,5 | 5,5 | - | Rest | <4 | - | 25-30 HRC/40 HRC* | |||

| DUROLIT 25 | 0,1 | 1 | 0,5 | 20 | 10 | - | 14,5 | Rest | <4 | - | 250-280 HB | Pumps, chemical industry, hot shear blades, valves. | Weld metal of austenitic structure. Very good machinability. Resistant to corrosion, impact, wear as well as extreme thermal shocks. | DIN EN 14700: T Z Co1 / DIN 8555: MF 20-300-CKTZ |

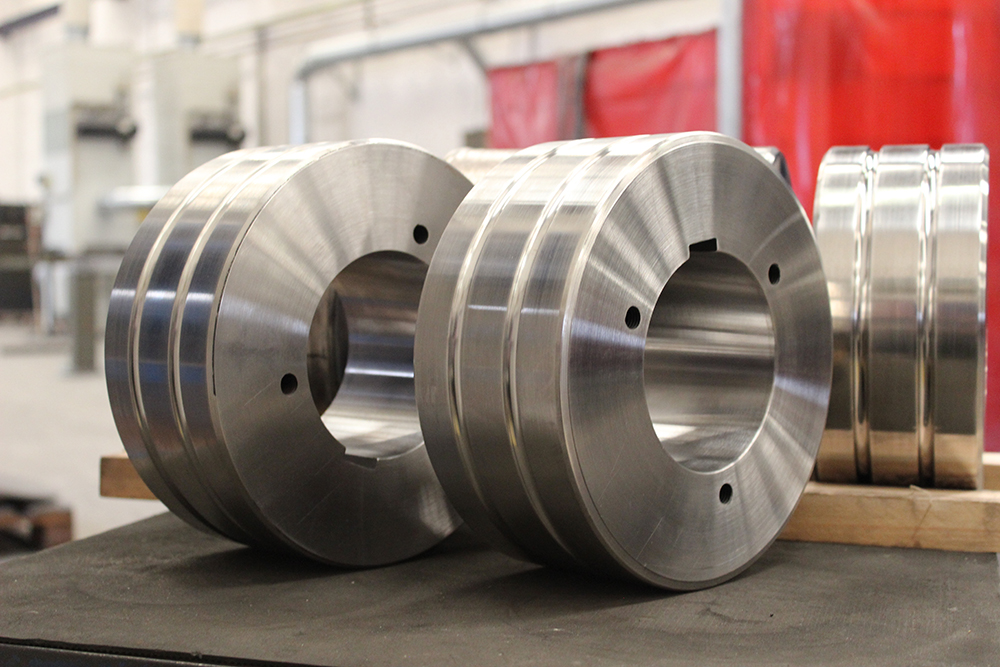

| DUROLIT 712 | 1,8 | 0,5 | 0,5 | 29 | <3 | 9 | - | Rest | - | - | 50 - 55 HRC | Conveyor and extrusion screws, rock bits, wear rings, impellers | Corrosion resistant in reducing acids High wear resistance | DIN EN 14700: T Z Co1 / DIN 8555: MF 20-300-CKTZ |

*Stellite is a registered trademark of Kennametal Stellite Company

- Request information material

Notice: The mandatory field is marked. All other fields are voluntary. Your data will only be collected and stored electronically strictly for the purpose of processing and responding to your request. Information on data processing can be found here: Privacy.

More products

Nickel base (Ni)

Nickel base (Ni)

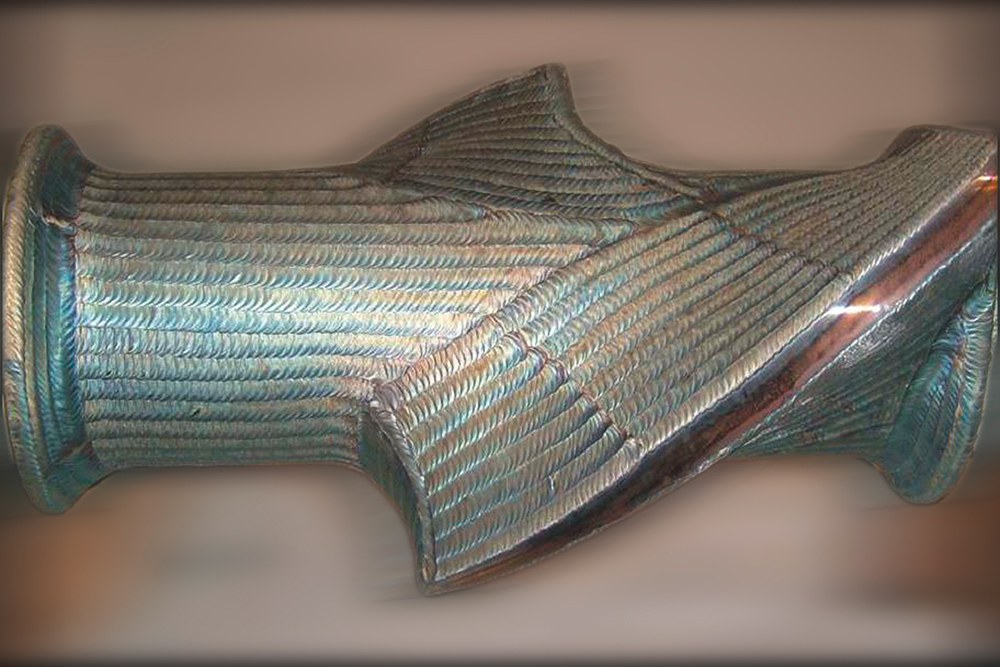

The main field of application is armoring of hammer saddles, hot shear blades, stretching inserts.

About the product

DURUM - Made in GERMANY

We manufacture our wear protection solutions for you exclusively in Germany.