Overview of wear applications

| Solid - Solid | Sliding wear | Guide rail, slide rail | Fe1, Fe2, Fe3, Cu1 | A, B, C, T |

|---|---|---|---|---|

| Solid - Friction | Impact wear | Forging hammer | Fe9, Fe10, Al1, Ni1, Ni4 | G, H, S |

| Boundary friction | Impact wear | Rocker arm, cam | Fe1, Fe2, Fe3 | A, B, C |

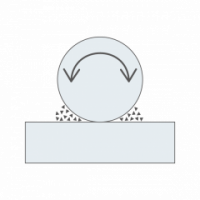

| Mixed friction | Rolling wear | Streetcar rail, switch | Fe9, Fe10 | G, H |

| Rolling wear | Impeller | Fe1, Fe2, Fe3, Fe9 | A, B, C, G |

| Rolling wear | Strand guide roller | Fe7 | E | |

| Impact wear | Roller table roller | Fe3, Fe6, Fe7, Fe8 | C, E, F | |

| Thermal shock | Driver roller, reel | Fe3 | C | |

| Forging die | Fe3, Fe4, Fe6, Fe8, Co1-3, Ni2, Ni4 | C, D, F | |

| Shock sliding wear, cold | Shear blade, cutting edge | Fe4, Fe5, Fe8, Co1-3 | D, F, O | |

| Shock sliding wear | Hot shear blade | Fe3, Fe4, Co2, Ni2, Ni4 | C, D, P, S | |

| warm | Perforated mandrel | Fe3, Fe4, Co2, Ni2, Ni4 | C, D, P | |

| Solid - Solid | Shock sliding wear | Crusher jaws, crusher hammer | Fe6, Fe8, Fe9, Fe14 | F, G, L |

| With particles | Impact bar | Fe6. Fe8, Fe9 | F, G | |

| Spinebreaker | Fe6, Fe8, Fe9, Fe13-15 | F, K, L, M, N | |

| Grate bar, grate beam | Fe13-15 | K, L, M | ||

| Coal mill beater | Fe8, Fe13-15 | F, K, L, M | ||

| Wear plate | Fe13-15 | K, L, M | ||

| Solid - Particle | Impact wear | Plowshare, bucket knife | Fe15, Fe20, Ni20 | M |

| High surface pressure | Sliding wear | Discharge tables, chute | Fe14, Fe15, Fe20, Ni20 | L, M |

| and shock | Wear plate | Fe14, Fe15, Ni1-4, Ni20 | L, M | |

| Solid - Solid | Furrow wear | Extruder | Fe14, Fe15, Fe20, Ni1, Ni3, Ni20, Co1-3 | L, M, P, Q |

| and particles | Screw conveyor | Fe14, Fe15, Fe20, Ni1, Ni3, Ni20, Co2, Cr1 | L, M, P, Q | |

| High surface pressure | Bucket knife | Fe15, Fe20, Ni20 | M | |

| Fang, Ripper | Fe2, Fe6, Fe8 | B, F | |

| Mixer part, mixer bottom | Fe6, Fe8, Fe14, Fe20, Ni1, Ni3, Ni20 | F, L, Q | ||

| Brick press mold | Fe6, Fe8, Fe14, Ni1, Ni3 | F, L | ||

| Grinding segment, grinding ring | Fe14 | L | ||

| Solid - Particle | Grain sliding wear | Blast furnace valve, blast furnace gas valve | Fe6, Fe7, Fe8 | E, F |

| and gas | (T>500°C) | Gout bell, seat | Fe3, Fe6, Fe8, (Fe16) | C, F, (N) |

| Blast furnace charging hopper | Fe15, Fe16 | M, N | |

| Furnace fittings, slide valves | Fe7, Co1, Co2 | E, O, P | ||

| Fan blade | Fe10, Fe15, Fe16, Fe20, Ni1-4, Ni20 | H, M, N, Q | ||

| Spike crusher, wear plate | Fe14, Fe15, Fe20, Ni1, Ni3, Ni20 | L, M, Q | ||

| Solid - Liquid | Flushing wear | Steel piping | Fe14, F15 | L, M |

| and particles | Erosion | Sea dredging guides | Fe6, Fe8 | F |

| Fluid pump | Fe6, Fe7, Fe8, Ni1, Ni3 | E, F | |

| Mixer parts | Fe6, Fe7, Fe8 | E, F | ||

| Erosion, corrosion | Propeller | Cu1 | T | |

| Water turbine | Fe7, Cu1 | E, T | ||

| Solid - Liquid | Corrosion | Chemical apparatus | Fe7, Fe11, Fe12 | E |

| Fitting sealing surfaces | Fe7, Fe11, Fe12 | E, O, P | ||

| * Alloy group according to DIN EN 14700:2014 ** Alloy group according to old DIN 8555-1 |

||||