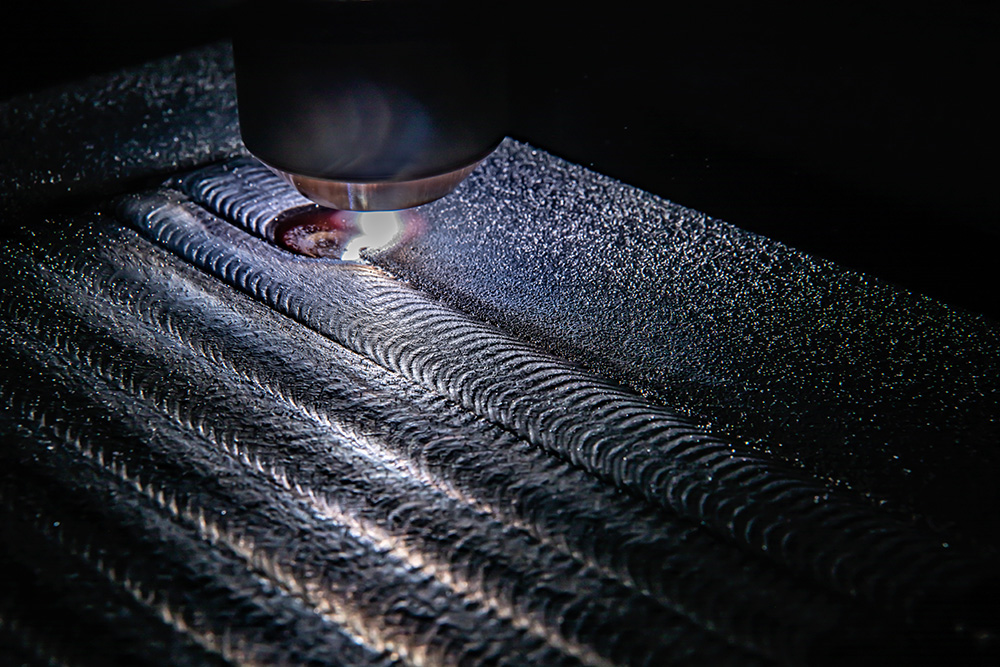

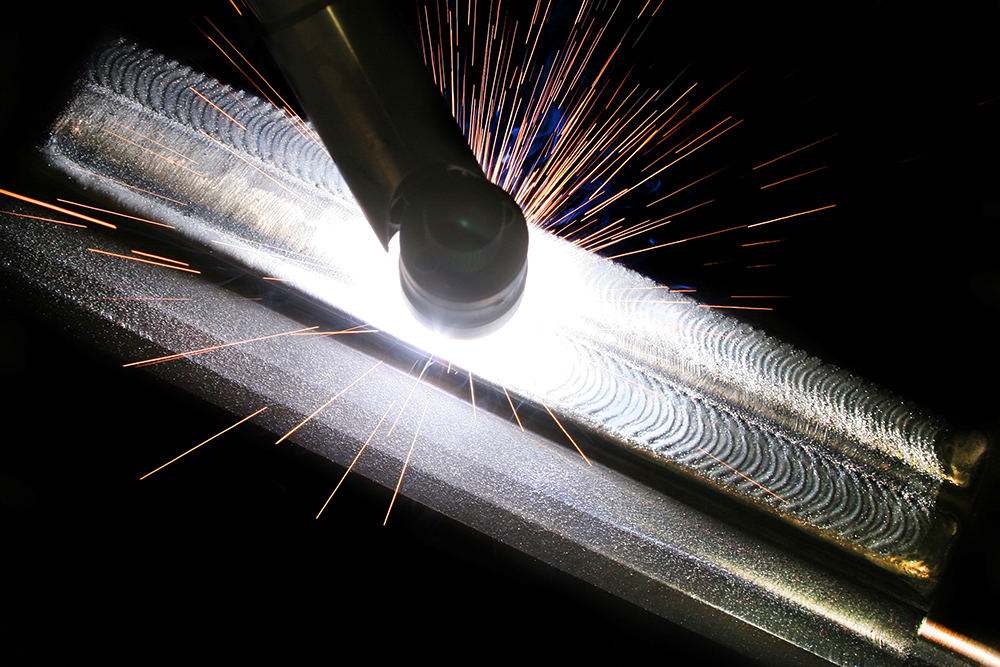

DURMAT® PTA welding powder for plasma powder buildup welding

DURMAT® PTA welding fluxes enable the deposition of many materials and material combinations in plasma powder buildup welding and offer a High wear resistance.

| DURMAT® | Typical chemical composition (matrix in wt.-%): | Matrix hardness | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | B | Ni | Mo | Co | Nb | V | Fe | + | ||

| 33 PTA | - | 4,1 | - | 6 | 1 | Rest | - | - | - | - | 1,5 | - | 33 HRC |

| 40 PTA | <0.05 | 2,7 - 3,3 | - | - | 1,8 - 2,4 | Rest | - | - | - | - | - | <2 | ≈ 40 HRC |

| 54 PTA | 0,5 - 0,7 | 3,5 - 4,5 | - | 15 - 17 | 3 - 4 | Rest | 2 - 4 | - | - | - | <3 | Cu: 2 - 3 | 56 - 61 HRC |

| 55 PTA | 0,4 - 0,6 | 3,5 - 4,5 | - | 12 - 14 | 2,5 - 3,5 | Rest | - | - | - | - | 3,5 - 4 | - | 50 - 55 HRC |

| 56 PTA | 0,25 | 3,2 | - | 7,5 | 1,8 | Rest | - | - | - | - | <2.5 | - | 40 - 42 HRC |

| 57 PTA | 1 | 4 | - | 16 | 3,2 | Rest | - | - | - | - | 3,4 | - | 58 - 63 HRC |

| 59 PTA | <0.05 | 3 | - | - | 3 | Rest | - | - | - | - | <1 | - | 49 - 52 HRC |

| 77 PTA | <0.1 | <5 | - | - | <5 | Rest | - | - | - | - | <50 | - | 50 - 55 HRC |

| 401 PTA | <0.1 | - | - | 22 - 23 | - | Rest | 8 - 9 | - | 3,1 - 4,1 | - | <2 | WSC: 50 % | 240 - 300 HV0.1 |

| 411 PTA | <0.1 | - | - | 22 - 23 | - | Rest | 8-9 | - | 3,1 - 4,1 | - | <2 | SWSC: 50 % | 240 - 300 HV0.1 |

| 476 PTA | <0.1 | 0,6 | 1,2 | 15 | - | Rest | 16,5 | - | - | - | 3 | W: 4 | 250 HV30 |

| 625 PTA | 0,05 | - | - | 21 | - | Rest | 9,2 | - | 3,5 | - | 3 | - | 210 HV |

More PTA Welding Powder Products

Nickel base (Ni)

Nickel base (Ni)

The main field of application is armoring of hammer saddles, hot shear blades, stretching inserts.

About the product

DURUM - Made in GERMANY

We manufacture our wear protection solutions for you exclusively in Germany.